PRODUCTION

The thermal walls for facade are a peak achievement of the process of rationalizing the construction works.

They combine in one:

- facade tiling and its components (doors, windows),

- metal beams of the carrying construction of the building,

- thermal insulation of polyurethane and mineral wool,

- vapour - proof layer,

- interior facing,

- elements of the separate installations - electrical, heating, ventilation, solar collectors, photovoltaic panels and so on.

A facade thermal wall (application for patent) represents a high - quality modular element, manufactured and tested in factory conditions. Its fitting is quick and easy.

Technical specifications:

L x B x H = 2000 /4800 x 2400/3000 x 250/290 [ mm ]

Thermal conductivity U ≤ 0,09 - 0,13 [ W/m2 K ]

Weight – 65 - 78 [ kg/m2 ]

Without any sand, cement or metal reinforcement we manufacture the facade walls of the building in а factory and we integrate in it the thermal insulation – two in one.

The facing panels are modular units with various sizes. They are crafted with engineering precision and quality. Their assembly is really facilitated and the thermal insulation – seamless. Every single project is unique and there’s unlimited variety for the design of the modules.

The modular facing panels are patented.

The block modules for Bathroom and WC (application for patent) . They are ready to use immediately after their fitting and connection with the other installations of the building. Due to extremely efficient thermal insulation which prevents from temperature variations the cause for mould is eliminated.

Saunas and tepidariums can also be produced as block - modules.

Their heat losses are reduced to nothing. Their on-site fitting is very facilitated.

The floor slabs between the storeys are constructed of metal beams, and they consist of many layers in order to provide reliable durability and the necessary noise and thermal insulation.

The parts of the floor are manufactured and equipped in the factory and after their fitting the finishing covering of the floor is applied. Тhe latter can be any available on the market.

The foundation of the passive house is considerably lighter in weight because it carries 10 times less load in comparison with the conventional buildings. The ground slab integrates connecting elements for securing the walls and elements of the water supply and heating installations. It is casted on top of hard polyurethane.

Due to the exceptional thermal insulating properties and elasticity of polyurethane, the building erected on such a slab does not receive the negative impact from the ground, meaning:

- the forces during an earthquake are eliminated and this makes it seismicly proof.

- the heat losses through the foundation are very little.

download graphic in PDF

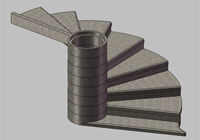

We pay special attention to staircases in order to achieve stability, fire - resistance and lack of noise. Their production of reinforced concrete and facing of stone or tiles takes place in the factory. To make it transportable we manufacture the staircase into separate modules.

One of the main requirements for the passive house is that its windows be situated as much as possible to the south.

The thermal conductivity of the glass and window frames should be:

U ≤ 0,8 [W/m2K].

The protection from heating in summer can be provided in various ways: Venetian blinds, outer grid, sun - protective glass etc. solutions which are agreed with the client.

The outer doors of the passive house comply with the high standard for the surrounding envelope of the building, i.e. their thermal conductivity is:

U ≤ 0,8 [W/m2K] .

The passive house is tested for airtightness (Blower-Door-Test) according to an internationally recognized method.

The roof is the part of the building which carries the highest heat load.

Quality thermal and noise insulation, air and water tightness, vapour permeability and other requirements are obligatory for constructing the roof without thermal bridges. Our company uses monopanels (utility model) and sandwich panels for seamless, airtight construction of the roof without thermal bridges.

The coefficient of thermal insulation is in the range of:

U ≤ 0,156 - 0,098 [ W/m2K ]

Dimensions:

L x B x H = 1220 x 2440 x 100 / 240 [mm]

Weight

G ~ 25 - 35 [kg/m2]